Video measuring machines, also known as video measuring systems, or video profile projectors are highly sophisticated machines used in industrial manufacturing and quality control. These machines use optical technology and advanced software to accurately and precisely measure various components and parts of machines. Video measuring machines have become increasingly popular over the years due to their high accuracy, speed, and ease of use.

The primary purpose of Video measuring machines is to measure the dimensions and features of small to medium-sized objects with high precision and accuracy. They use high-resolution cameras to capture images of the object being measured and then use advanced software to analyze those images and provide accurate measurements. The machines can measure a wide range of dimensions, including length, width, height, depth, angles, and other geometric features.

One of the primary benefits of Video measuring machines is their high accuracy. Unlike traditional measuring methods, such as manual calipers or micrometers, video measuring machines can measure features with sub-micron accuracy. This level of precision is essential in industries such as aerospace, automotive, and medical manufacturing, where even small errors can have significant consequences.

Another benefit of Video measuring machines is their speed. These machines can take measurements in a matter of seconds, which can save time and increase productivity. They are also very easy to use, and most models feature user-friendly software that can guide operators through the measurement process.

Video measuring machines are used in a wide range of industries, including aerospace, automotive, medical, and electronics manufacturing. In the aerospace industry, video measuring machines are used to measure the dimensions of components such as turbine blades and other critical parts. In the automotive industry, these machines are used to measure the dimensions of engine components and other critical parts. In the medical industry, video measuring machines are used to measure the dimensions of surgical implants and other medical devices.

Video measuring machines come in different types, including benchtop models and floor-standing models. Benchtop models are smaller and more compact, making them ideal for use in smaller manufacturing facilities or laboratories. Floor-standing models are larger and more robust, making them ideal for use in larger manufacturing facilities.

In conclusion, video measuring machines are highly sophisticated machines used in industrial manufacturing and quality control. They provide high accuracy, speed, and ease of use, making them an indispensable tool in various industries such as aerospace, automotive, and medical manufacturing. The demand for these machines is expected to continue to grow as manufacturers increasingly require high-precision measurements to meet their quality standards.

VMM ME

Manual Vision Measuring Machine

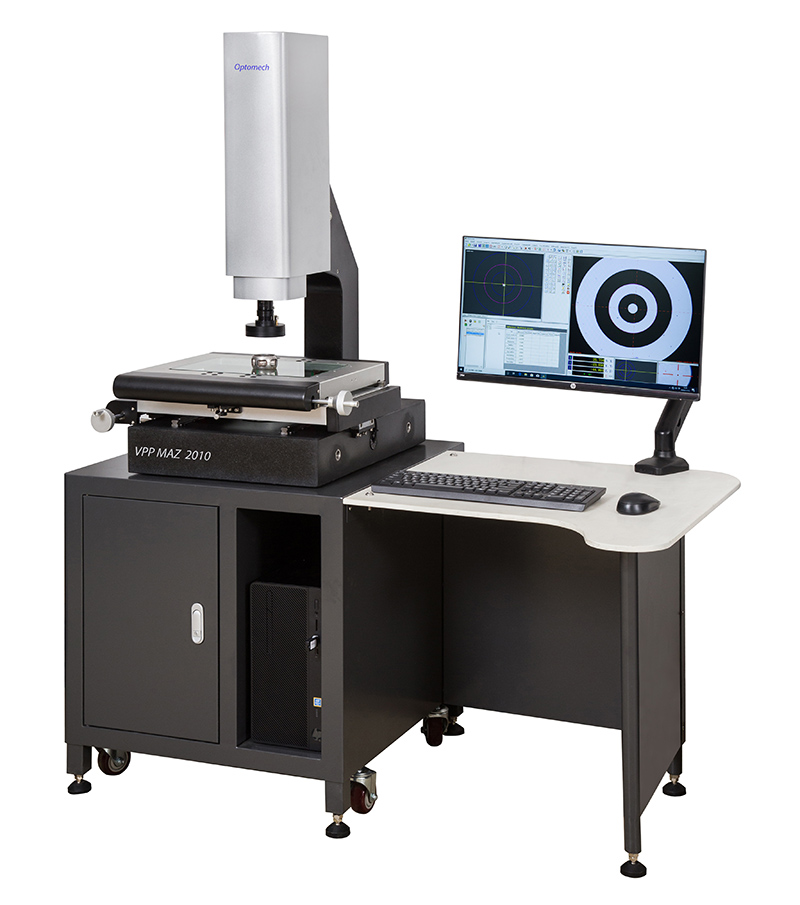

VMM MAZ

Vision Measuring Machine with Autofocus

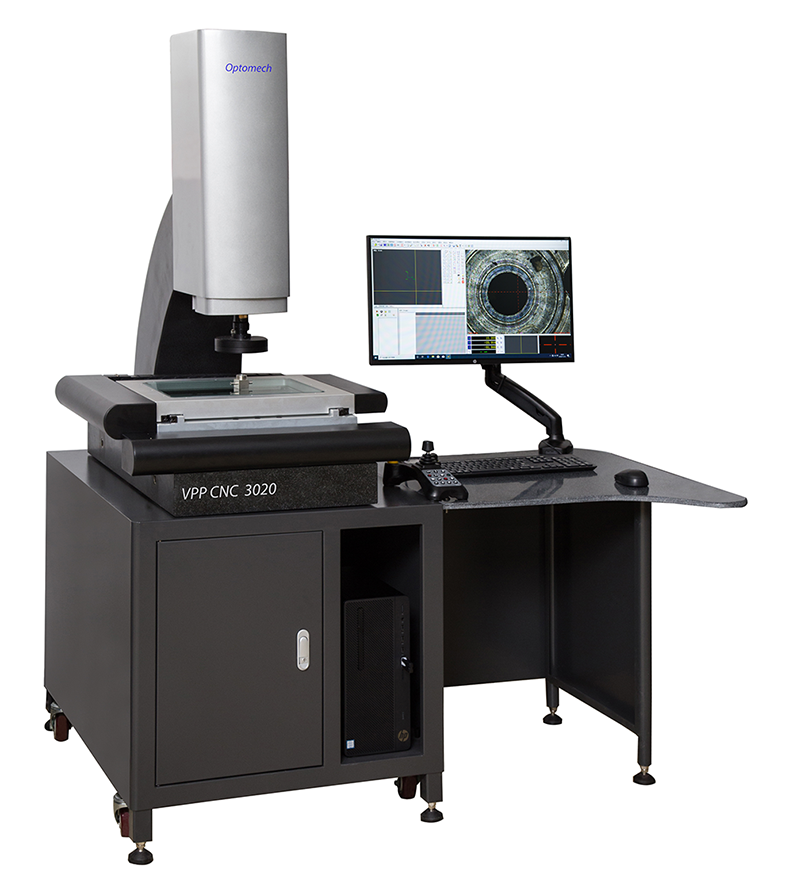

VMM CNC

Automatic, 3D, Vision Measuring Machine

- Precision X Y stage movement on cross roller guides with screwless drive.

- High resolution CCD Camera.

- Motorized zoom Lens with magnification upto 200x.

- LED profile illumination system.

- 4 Quad LED surface illumination system.

- Programmable LED surface and profile illumination system.

- Z axis with autofocus detection facility.

- Latest configuration computer with monitor.

- Advanced metrology software with user friendly graphical user interface.

Equipment is capable of:

- Generating and storing imaginary points such as centre of a circle/arc and intersection of two lines.

- Finding the distance between two imaginary points like the center distance between two circles, within an accuracy of 5 microns.

- Create components drawing, using the measured coordinates and store in .Dxf

- 3D non-contact measurement by auto focus.

- 3D measurement with touch probe option.

Large size, automatic, 3D,

Video Measuring Machine

Automatic CNC controlled 3D measuring machines with touch probe

- Software controlled, servo motor driven X Y stage.

- High resolution CMOS Camera.

- Motorized zoom Lens with magnification upto 200x.

- LED profile illumination system.

- 8 Quad LED surface illumination system.

- Programmable LED surface and profile illumination system.

- Z axis with autofocus detection facility for height measurement.

- Latest configuration computer with monitor.

- CNC controlled motorized X,Y and Z axis movement.

- Advanced metrology software with user friendly graphical user interface.

Equipment is capable of:

- CNC part programming capability.

- 3D measurement with touch probe option.

- Height measurement by auto focus.

- Create components drawing, using the measured coordinates and store in .Dxf

- Finding the distance between two imaginary points like the center distance between two circles, within an accuracy of 5 microns.

- Generating and storing imaginary points such as centre of a circle/arc and intersection of two lines.

CNC Video Measuring Machine:

A CNC Video Measuring Machine is equipped with advanced technology to accurately measure intricate components with precision. Its features include high-resolution cameras, automated measurement capabilities, and sophisticated software for data analysis. With programmable settings, it ensures consistent and reliable results, making it ideal for industries like aerospace, automotive, and electronics where precision is paramount.

Use of Video Measuring Machine:

Video measuring machines are invaluable tools for quality control and inspection tasks in manufacturing. They facilitate non-contact measurement of complex parts, ensuring accuracy and repeatability. These machines are particularly useful for inspecting dimensions, contours, surface finish, and defects in components, enabling manufacturers to maintain high standards of quality and efficiency in production processes.

Price of Video Measuring Machine in India:

The price of a video measuring machine in India varies depending on factors such as brand, specifications, and additional features. Generally, entry-level models may start from around INR 5 lakhs, while high-end systems with advanced capabilities can cost several lakhs or even crores.

Build Your Coordinate Measuring Machine:

Building your coordinate measuring machine allows customization to meet specific measurement needs. Starting with a robust frame, you can integrate precise linear motion systems, high-resolution cameras, and sophisticated software for accurate measurements. Customization enables versatility, making it suitable for various applications across industries like manufacturing, research, and metrology. With careful planning and selection of components, you can create a cost-effective solution tailored to your requirements.